How to Prepare Your Genset Before Monsoon & Storm Seasons

With Malaysia’s monsoon and ASEAN’s increasingly volatile weather patterns, reliable backup power is mission-critical. Whether you manage a factory, construction site, data room, farm, clinic, retail outlet, or a residential estate, getting your generator (genset) storm-ready protects people, equipment, and your bottom line. This practical guide covers pre-monsoon inspections, weatherproofing, fuel quality, hybrid microgrids with battery energy storage, and safe post-storm restarts so you can achieve true grid independence when it matters most.

1) Pre-monsoon inspection checklist

- Fuel system: Inspect for leaks, replace filters, and verify priming pumps. If diesel has been stored more than 6 months, treat for microbial growth (diesel bug).

- Cooling system: Top up coolant, pressure-test caps and hoses, and clear radiator fins. Overheating risk rises with high humidity and debris.

- Lubrication: Change engine oil and filters per OEM schedule. For mission-critical sets, send an oil sample to a lab to spot early wear.

- Belts and hoses: Replace cracked belts, bulging hoses, and brittle clamps. Keep spares on-site.

- Battery health: Test voltage and CCA, clean terminals, and check charger settings. Replace weak batteries proactively.

- Air intake and exhaust: Confirm unobstructed airflow. Replace clogged air filters and ensure rain caps and insulation are intact.

- Alternator and AVR: Inspect windings for moisture or dust buildup and confirm stable voltage regulation under load.

- Control panel and sensors: Verify alarms and sensor readings. If you use a smart controller, update firmware and test remote monitoring.

- Load bank test: Exercise the genset at 60–80% load to prevent wet stacking. Record kW, volts, Hz, and THD for baseline reference.

2) Weatherproofing and site readiness

- Elevation and drainage: If your site floods, raise the base frame or plinth. Ensure water drains away from the enclosure.

- Enclosure integrity: Check door seals, gaskets, louvers, and roof seams for water ingress. Consider IP-rated canopies for open sets.

- Cable management: Use UV-rated, water-resistant cables. Keep joints above likely flood levels; seal with heat-shrink and proper glands.

- Exhaust routing: Maintain clearances from windows and HVAC intakes. Add extensions if new flood barriers alter airflow paths.

- Lightning and surge protection: Bond the genset, ATS, and distribution to a verified earth. Install surge protective devices on mains and sensitive circuits.

3) Fuel readiness and quality control

- Runtime planning: Stock enough diesel for at least 24–48 hours based on calculated load and expected outage duration.

- Keep tanks dry: Use water detection paste and drain water bottoms. Add biocide if slime or microbial growth is present.

- Fuel polishing: For large tanks or long storage periods, schedule polishing to maintain cetane, clarity, and cleanliness.

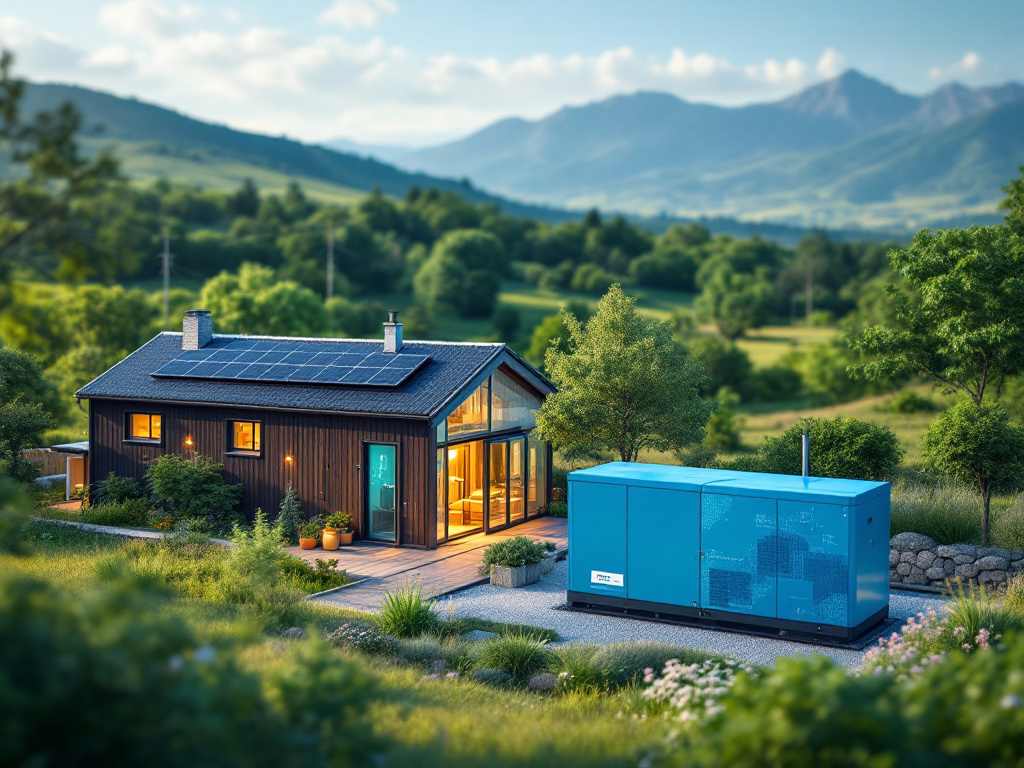

4) Power continuity planning: smart controllers + battery energy storage

Map your critical loads (IT racks, cold rooms, pumps, lifts, access control, lighting) and size your genset to handle them with headroom. A modern smart controller with an automatic transfer switch (ATS) ensures fast, safe switching. For the best efficiency and emissions profile, integrate a Battery Energy Storage System (BESS) to create a hybrid microgrid. The battery carries instantaneous load during switchover and efficiently serves low-load periods, while the generator operates in optimal bands—cutting diesel consumption, reducing noise, and improving sustainability. This renewable-ready approach supports future solar integration and true grid independence.

5) Safe operations during storms

- Pre-start checks: Verify fuel, oil, coolant levels, and that louvers/vents are unobstructed.

- Warm-up and stabilization: Allow voltage and frequency to stabilize before the ATS transfers load.

- Monitor in real time: Use the controller or remote monitoring to track load, temperature, and alarms. Never refuel a running genset unless the system is designed for it and procedures are in place.

6) Post-storm recovery: restart and maintenance

- Visual survey first: Check for debris, flood marks, moisture in the enclosure, and cable damage. Dry components thoroughly before energizing.

- Oil and filters: If runtime was extended, change oil and filters ahead of schedule.

- Cooling and intake: Clean radiators and replace air filters if clogged with dust or debris.

- Controller logs: Review event history for undervoltage, overtemp, or fuel pressure faults; resolve root causes.

- Document and schedule: Record runtime, fuel used, anomalies, and book a service visit if unusual vibration, noise, or smoke persists.

Right-size your genset for storm resilience

Choosing the correct capacity ensures stable operation and lower lifecycle cost. For SMEs and facilities that need dependable emergency power, popular sizes include the 60kVA MGM Generator and the 100kVA MGM Generator (Mark 12). Our engineers can also design hybrid systems with battery energy storage to optimize fuel usage and emissions while maintaining critical uptime.

Let’s safeguard your operations this monsoon

Need help with a pre-monsoon inspection, ATS testing, or a turnkey generator-plus-battery microgrid? Contact our engineering team for a site assessment and tailored recommendation. You can also reach us directly at genset@genset.com.my or call +60129689816. From smart controllers to premium MGM gensets and integrated BESS, we deliver reliable, sustainable energy solutions for Malaysia and the wider ASEAN region.

Keywords: power generators, battery energy storage, grid independence, renewable integration, emergency power solutions, innovative generator systems, sustainable energy, Malaysia, monsoon preparedness.